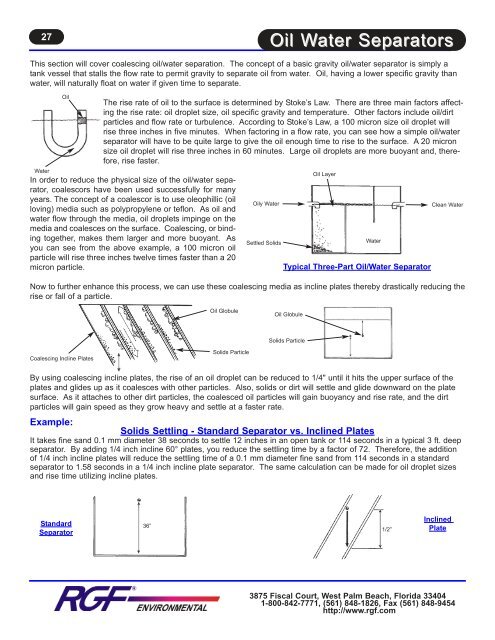

A 1947 api commissioned study from the university of wisconsin determined the coalescing plate separator design method used for removing oil from water in refinery effluent water.

Coalescing oil water separator design.

Determining the micron removal efficiency required to meet your effluent requirements ppm mg l is an important step in the design and sizing on oil water separators.

This media provides a suitable surface for oil droplets to meet and grow or coalesce into larger droplets.

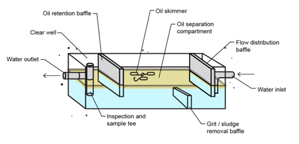

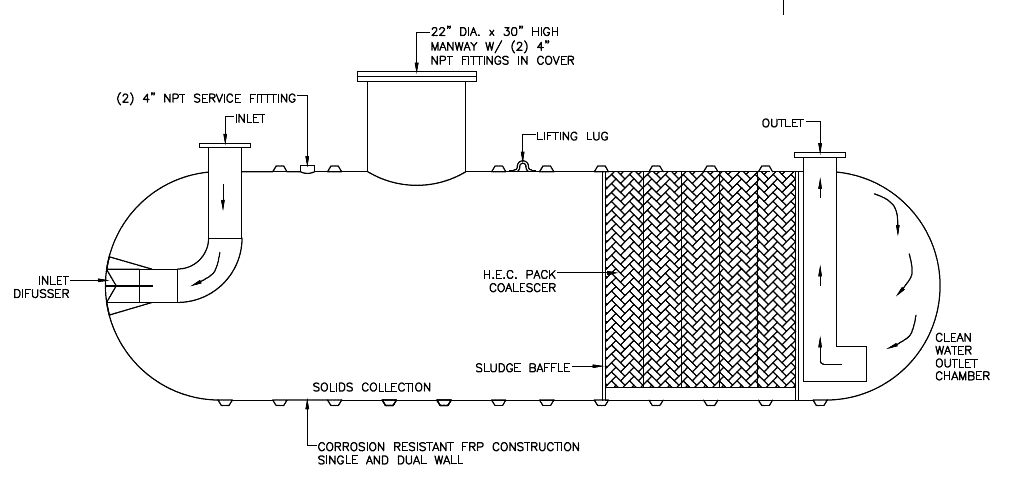

Separator designs may vary are liquid containment structures that provide sufficient hydraulic retention time to allow oil droplets to rise to the surface.

Conversely those designed to require less cleaning mainentance were unable to meet mandatory effluent requirements.

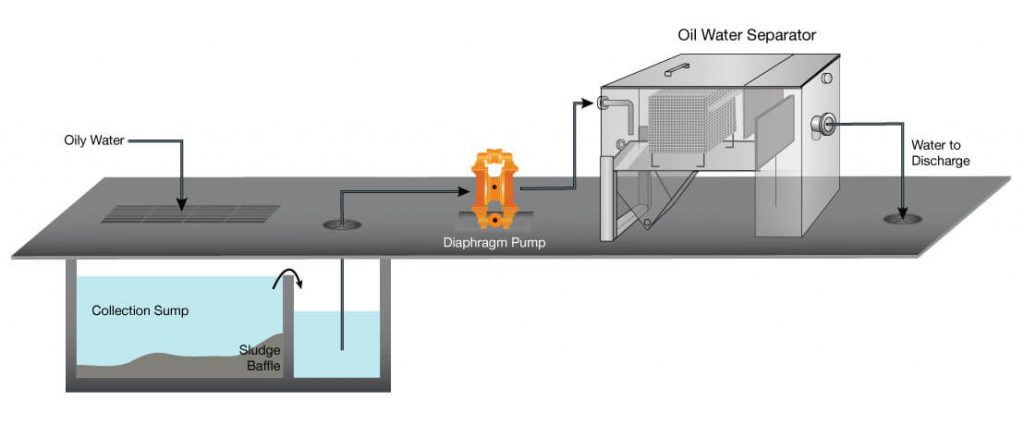

Applications include oil spill clean up for marine power plants refineries vehicle terminals and countless others.

Facility designers choose coalescing separators because they are smaller less expensive and require less site work than the equivalent simple gravity separators.

For over 50 years there has been tension in the design of mainstream oil water separator coalescer equipment.

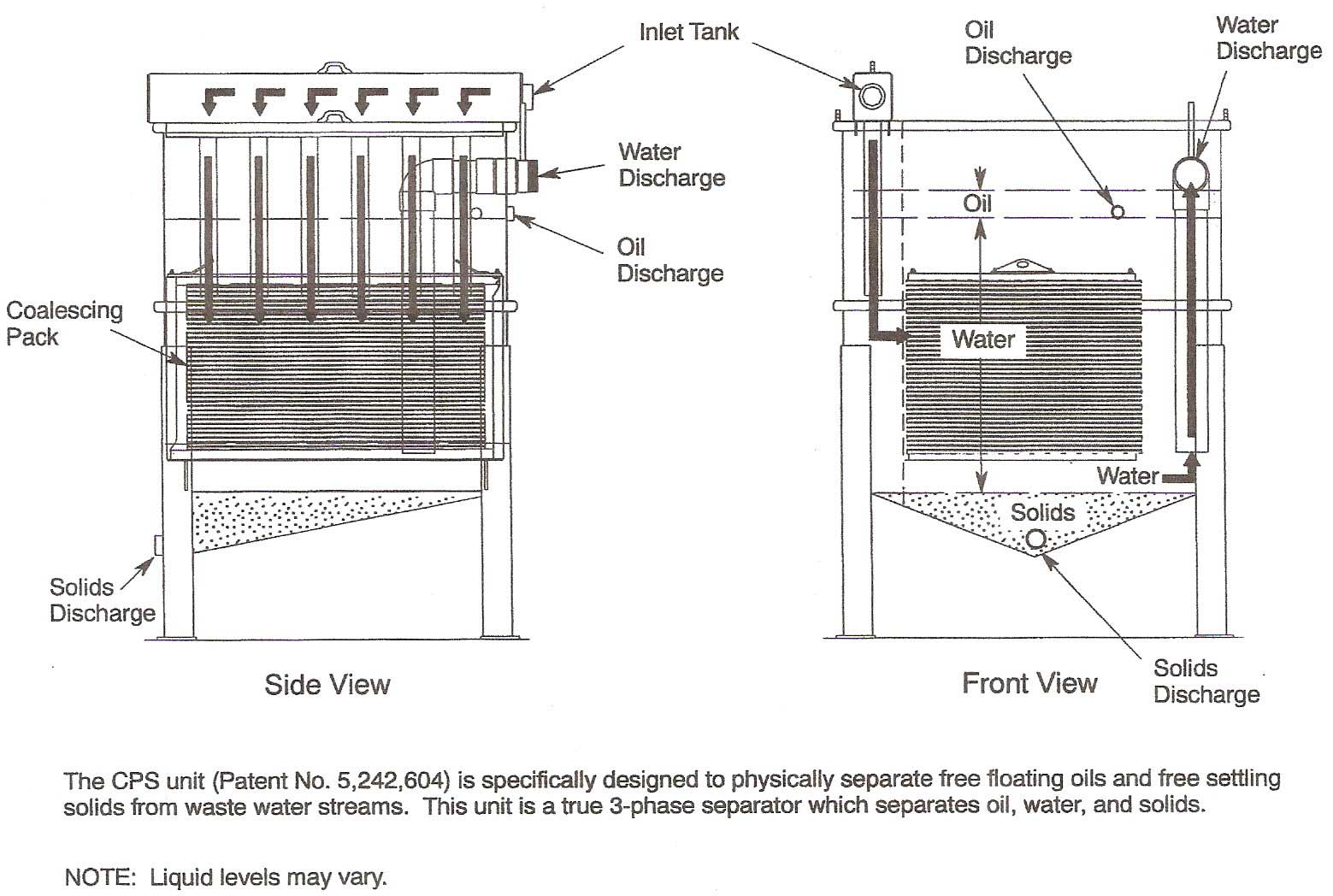

The separated water is purified for direct sewer or ocean discharge.

The design methods focused primarily on resource recovery and mitigating the nuisance effect of oil exiting the refineries and entering streams and lakes.

Many manufacturers now offer.

We offer two designs.

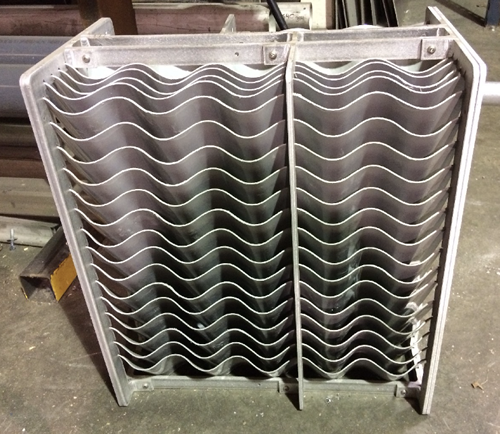

Coalescing devices come in different configurations.

Design of coalescing media for oil in water oil in water coalescing media how it works.

The separator cartridge is placed between the coalescing filter and the outlet to act like a screen which removes the tiny water droplets.

Oil water separators function based on stokes law.

The droplets are too tiny to respond to the force of gravity within the short distance provided for within the filter unit.

Liquid liquid coalescer design manual acs oil water separatorsutilize patented technology to separate oily waste water.

As oil droplets grow in size the buoyancy of the droplets increases.

Media pack separators and plate separators.

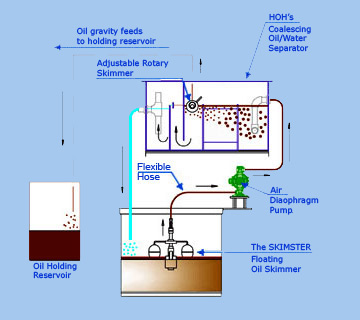

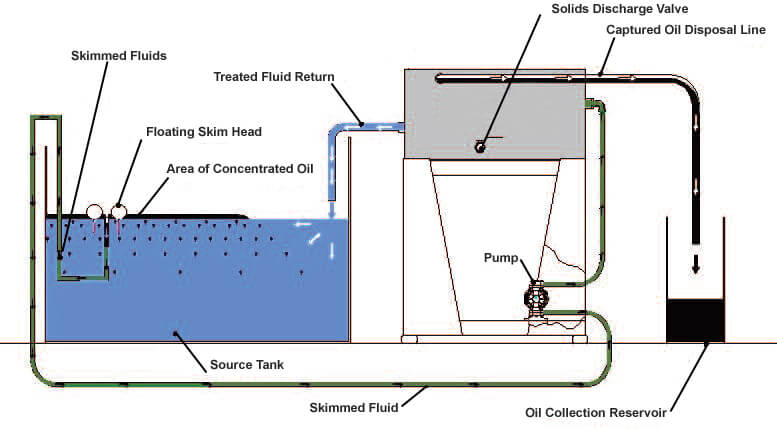

The oil forms a separate layer that can then be removed by skimmers pumps or other methods.

An oil water separator or ows contains coalescing media.

-6-resized-600.jpg)