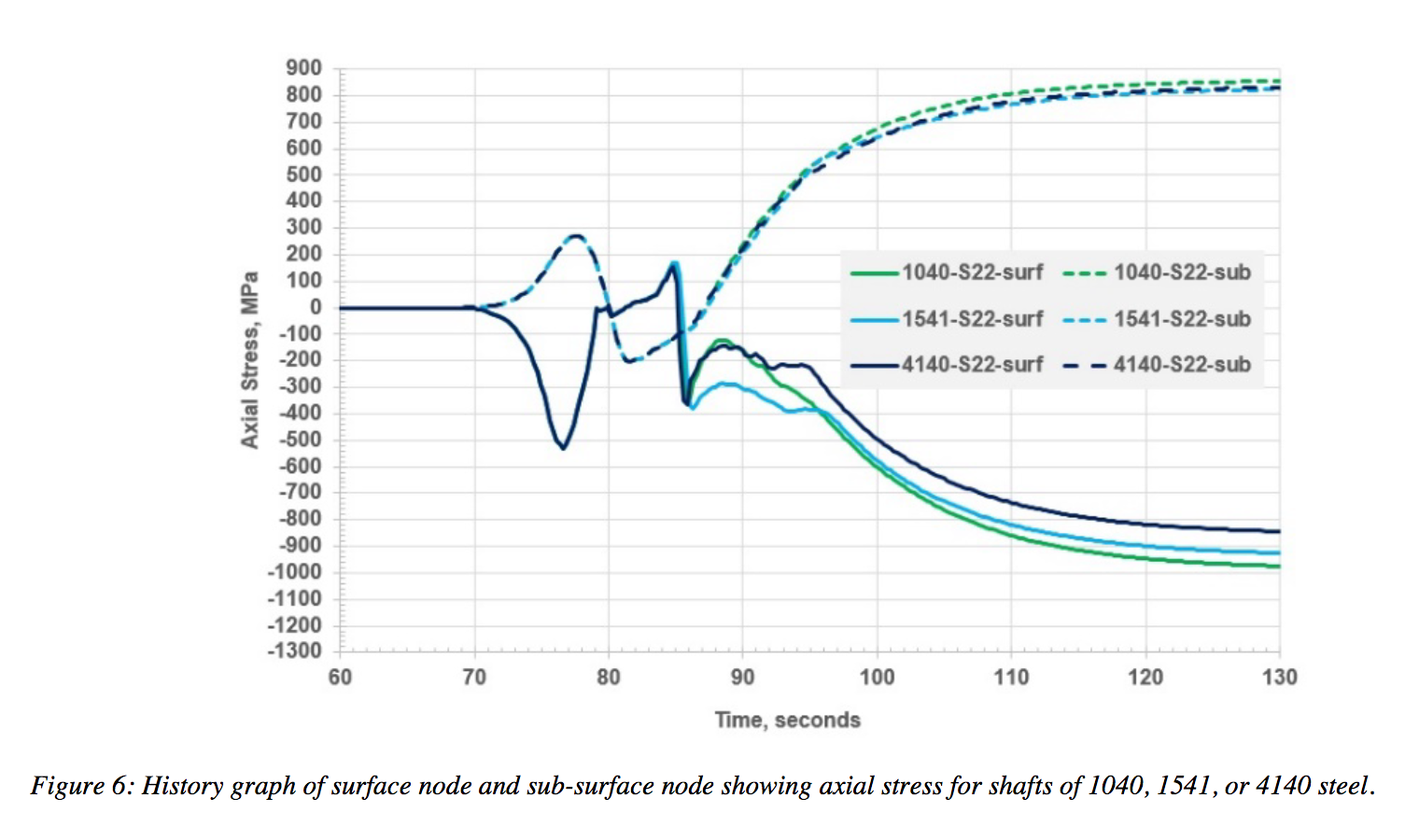

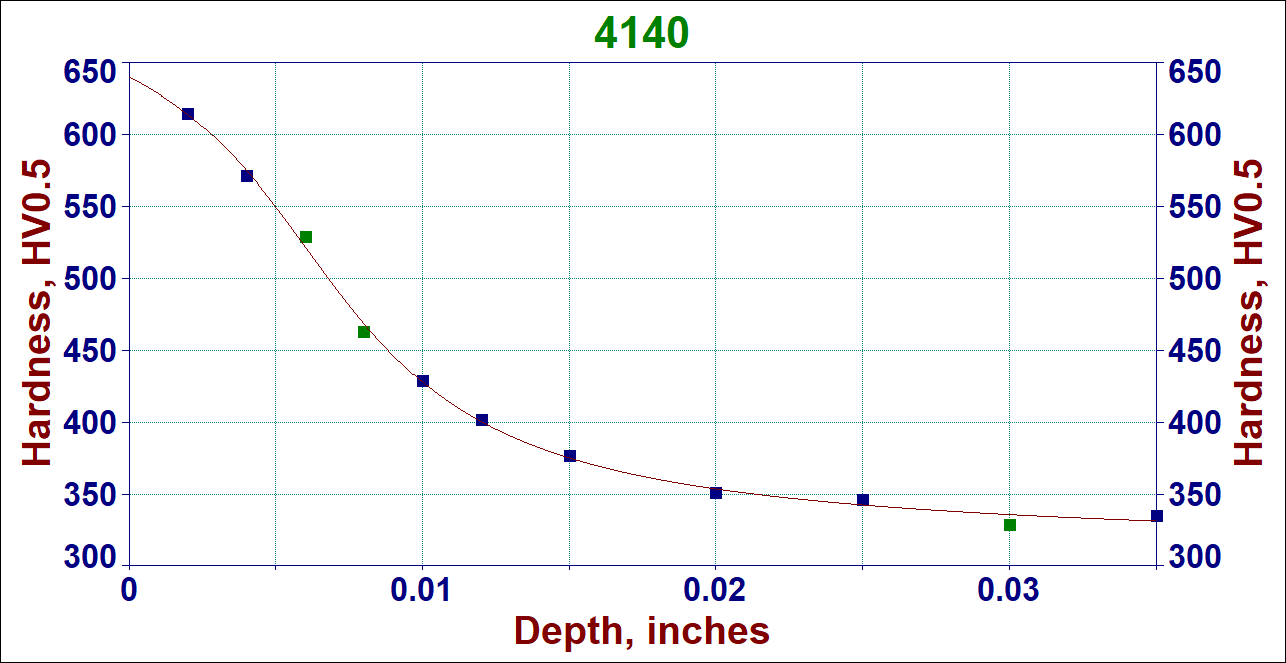

4140 is a 1 chromium molybdenum medium hardenability general purpose high tensile steel generally supplied hardened and tempered in the tensile range of 850 1000 mpa condition t 4140 is now available with improved machinability which greatly increases feeds and or speeds while also extending tool life without adversley affecting.

Flame hardening 4140 steel.

Its chromium content provides good hardness penetration and the molybdenum imparts uniformity of hardness and high strength.

C4140 responds well to heat treatment and is comparatively easily machined in the heat treated condition.

Workability alloy c4140 is an oil harden ing steel of relatively high hardenability.

You will need to watch your steel carefully as it goes through several different color changes until it passes blue hot and finally becomes red hot.

After that the steel is cooled in a furnace.

Hardening steels involves the basic process of heating the steel to organize the crystalline structure in a uniform way and then rapidly cooling it by quenching it to lock the molecular make up of the steel.

How to flame harden steel using your blow torch or a furnace with a bellows heat your steel until it glows red hot.

On the other hand 4140 steel has tampered at the temperatures of between 200 c and 650 c.

Below is an outline of the process that follows thereafter.

4140 steel is annealed at 872 c which is equivalent to 1600 f.

4140 is relatively easy to harden.

Flame hardening process of flame hardening 4140 other steel grades of machined parts and stampings flame hardening sometimes begins with a preheat operation depending on the alloy and degree of machining.

In this video we give some basis on how to get some 4140 alloy steel hardened and then temper to different hardness we will perform our test using a rockwel.

.jpg)

.jpg)