Wei y et al effect of tool pin insertion depth on friction stir lap welding of aluminum to stainless steel.

Friction stir welding aluminum to stainless steel.

The strength of the joints was dependent on the probe diameter of fsw tools when the sound welds were obtained with radiographic testing rt and ultrasonic testing ut.

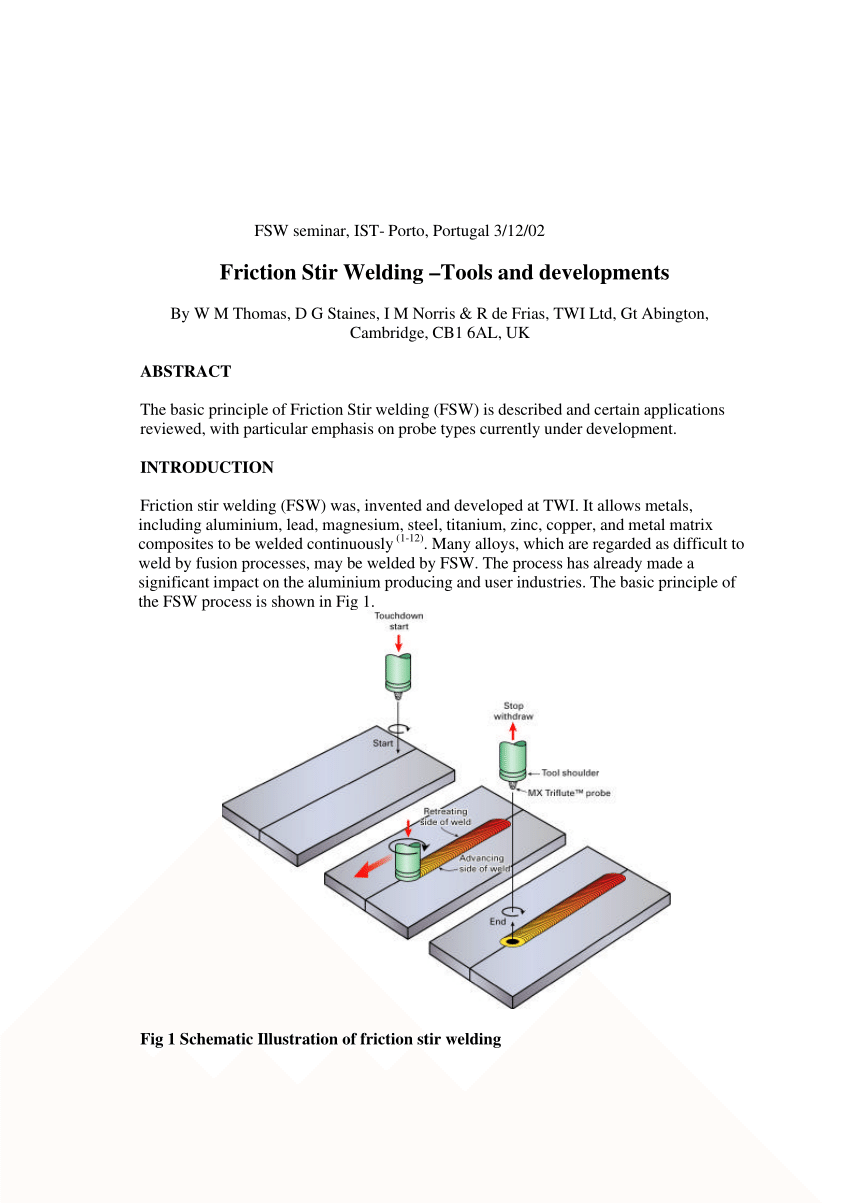

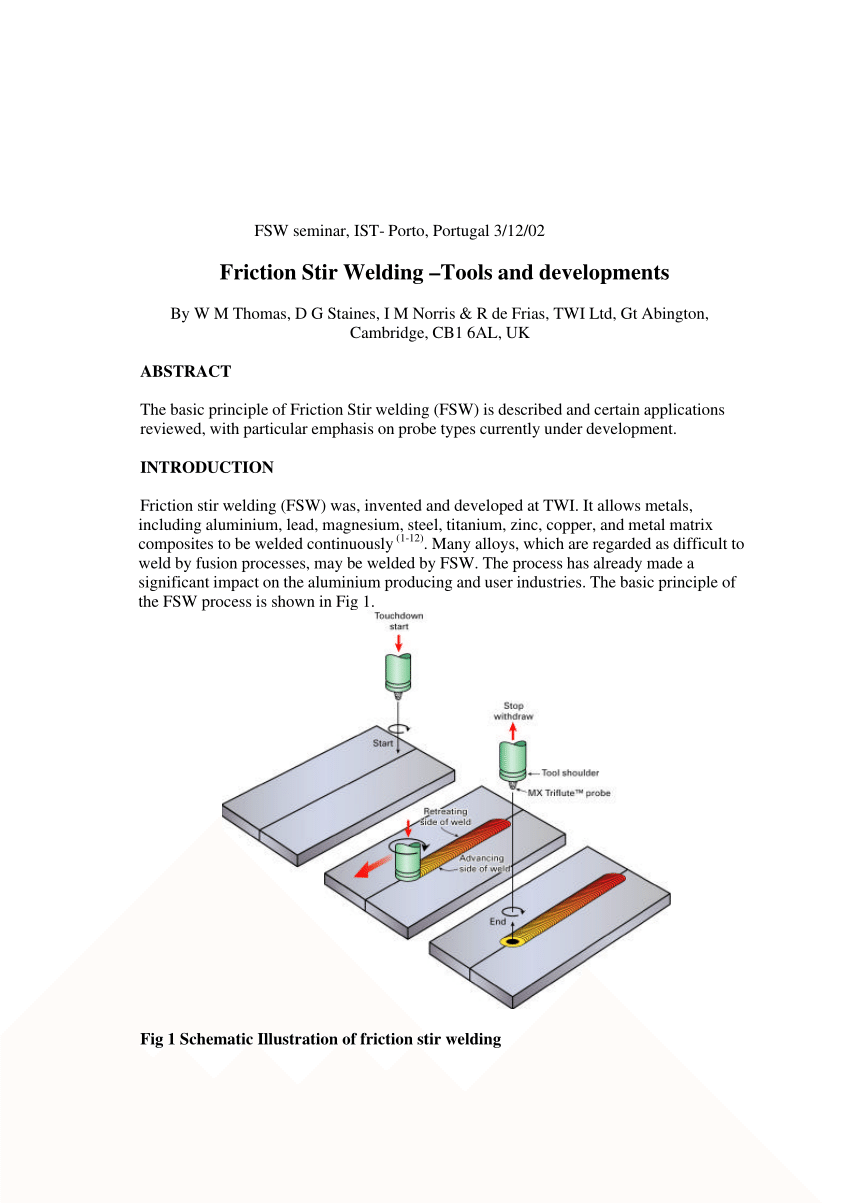

Friction stir welding fsw was applied to dissimilar metal lap joints of thick plates between a3003 aluminum alloy and sus304 stainless steel.

Journal of materials engineering and performance 2013.

Welding experiments were carried out using wc co tools with different pin profiles.

6xxx alloys are generally the easiest to friction stir weld and constant improvements in tool design and process control have permitted the welding speed to be drastically improved.

When friction stir welding was first introduced commercially extrusions such asaa6082 t6 were welded at about 0 7 to 0 8m min with a joint line thickness of 5 to 6mm.

A tungsten carbide tool with a tapered cylindrical pin has.