This article showcases details on enumerative information of dissimilar aluminum al to steel welds manufactured using different friction based welding processes with an emphasis on the description of the manufacturing process influence of parameters microstructural variations formation of intermetallic compounds imcs and variations in mechanical properties.

Friction welding to join stainless steel and aluminum materials.

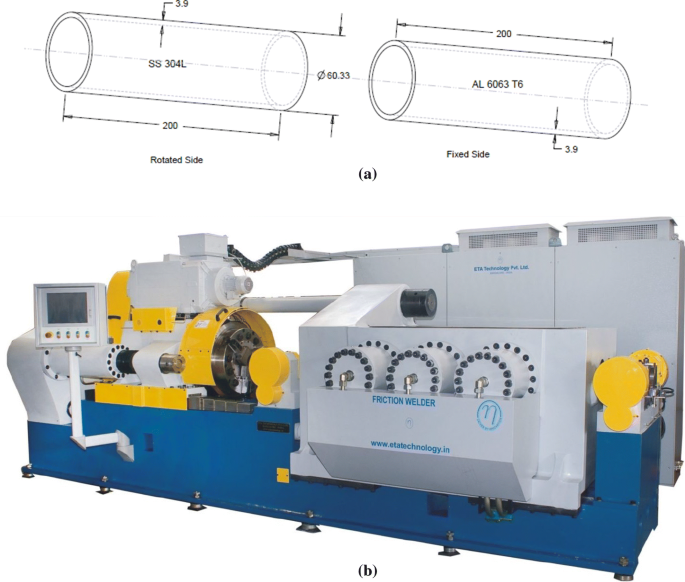

Friction welding to join stainless steel and alumin um materials 1shubhavardhan r n 2surendran s 1iit madras chennai 600036 chennai tamil nadu india 2professor iit madras chennai tamil nadu india abstract the purpose of this work was to join and assess the development of solid state joints of dissimilar.

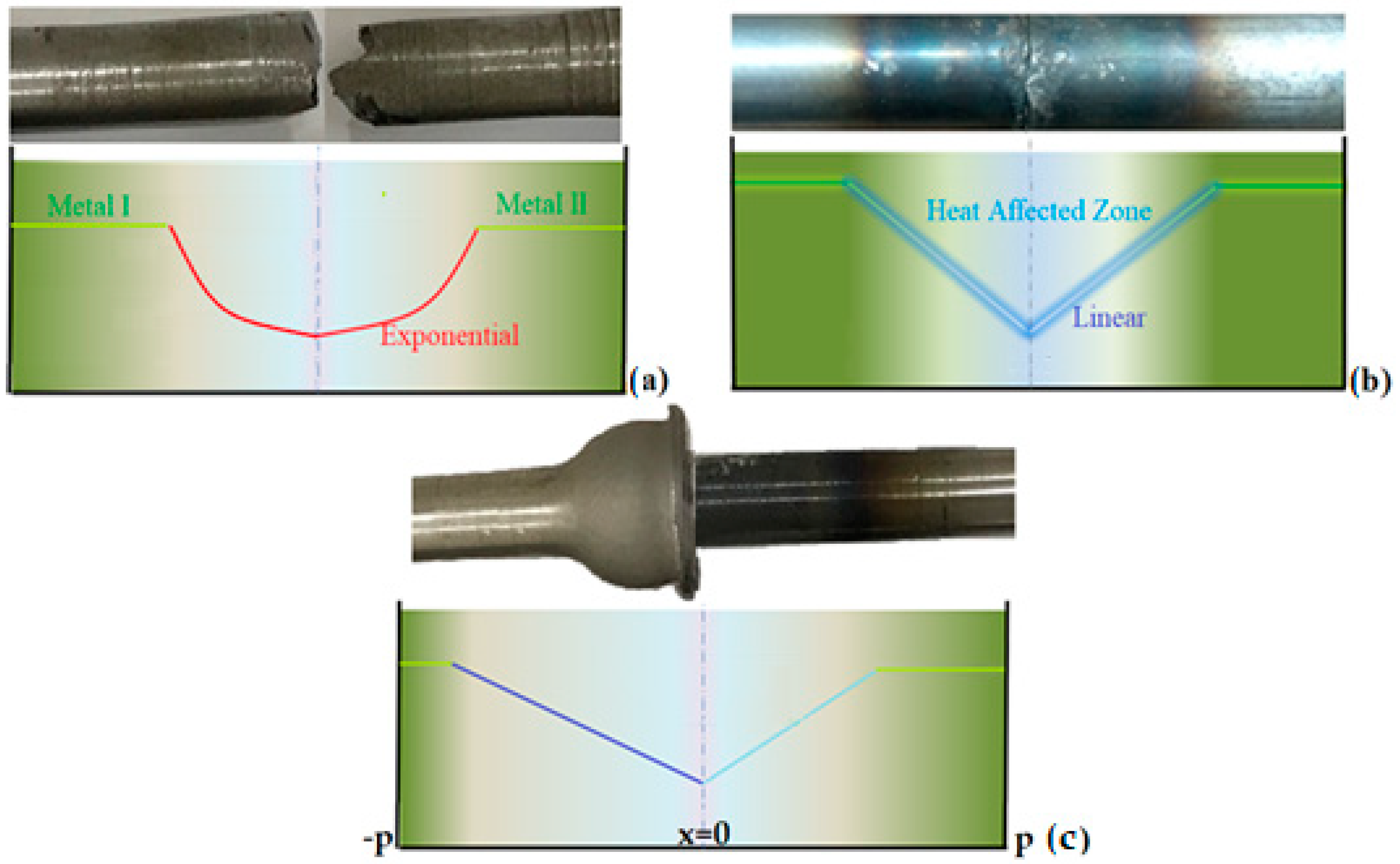

Because no melting occurs friction welding is not a fusion welding process in the traditional sense but more of a forge welding technique.

By 6mm wall tube.

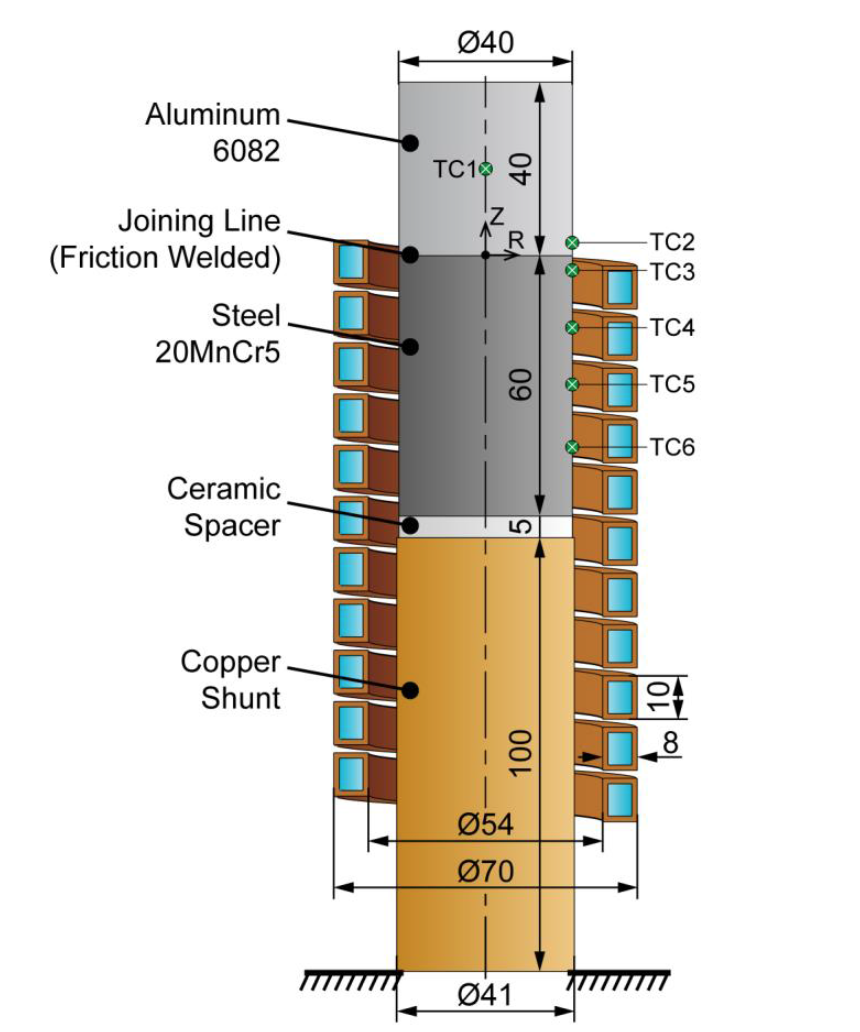

Shubhavardhan rn and surendran s 2012 investigated to join and assess the development of solid state joints of dissimilar material aa6082 aluminum alloy and aisi 304 stainless steel via.

Friction welding to join stainless steel and aluminum materials 69 the soft ware al lowe d p iloting of t he be am s canning along a surface or a line to.

The technique of using a silver electroplated interlayer when friction welding aluminium alloys to stainless steels has been investigated for two aluminium alloys 5083 and 5154a and three component geometries 25mm diameter solid 25mm o d.

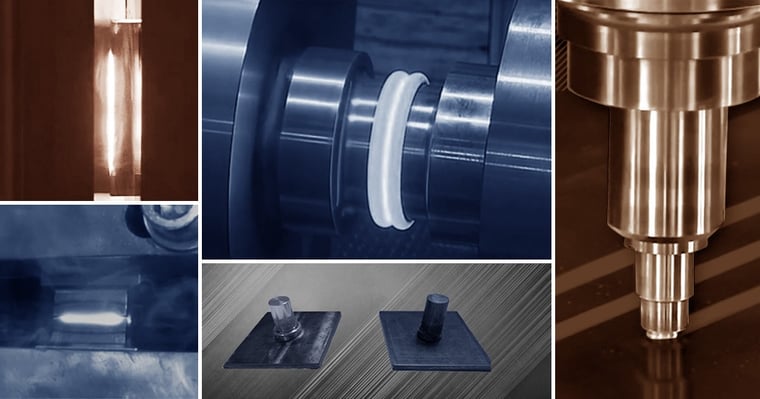

Friction welding frw is a solid state welding process that generates heat through mechanical friction between workpieces in relative motion to one another with the addition of a lateral force called upset to plastically displace and fuse the materials.

The problems encountered in friction welding during joining of austenitic stainless steel are very limited when compared to fusion welding process.

Copper aluminum using linear friction welding we can join copper to aluminum to form a heat.

Doing so is a cost effective way of getting the benefits from both materials.

Friction welding of similar dissimilar bi metal weldable materials inertia and direct friction welding have the advantage of joining metal and bi metallic combinations of weldable materials.

The studies have undergone with joining of austenitic stainless steel and copper material to evaluate the friction welding parameter for finding the good bond strength.

2011 reported the comparative studies on the relationship between the welding parameters and joining efficiency in the friction welding of hybrid al 2 o 3 reinforced aluminum composites the effects of the rotation speed on the reduction rate of particle size are greater than those of the upset pressure and the area of the mmc welded zone decreases as the joining efficiency.

Typically we can use any of the friction welding technologies to weld dissimilar metals and the following are some common bi metallic combinations and applications.