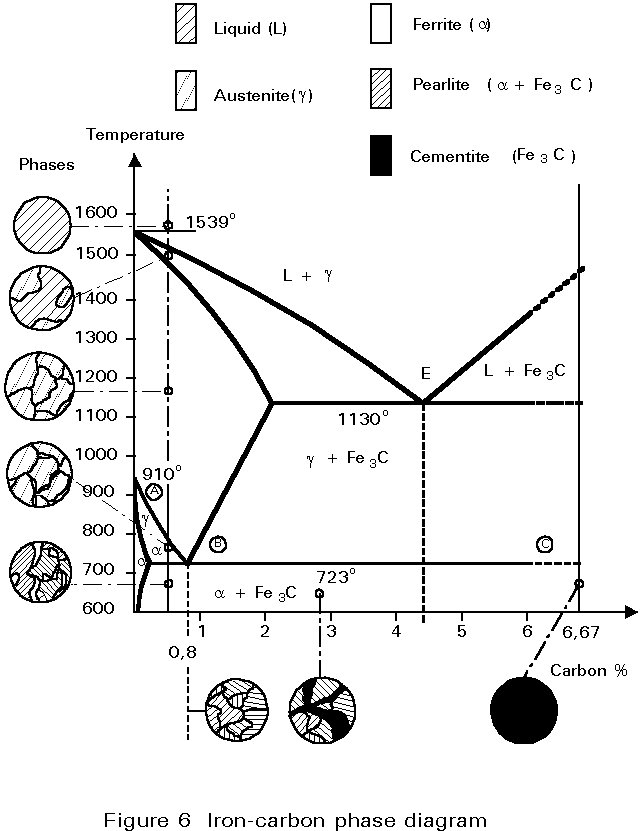

The start of solidification is described by the liquidus line and the end of solidification by the solidus line the microstructure is formed between these lines with a correspondingly slower cooling rate.

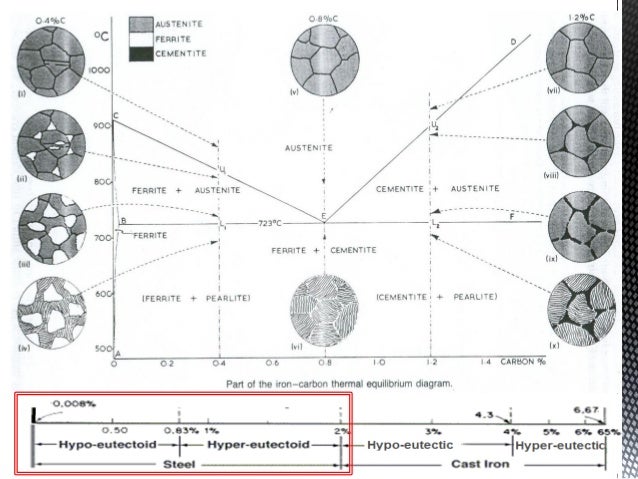

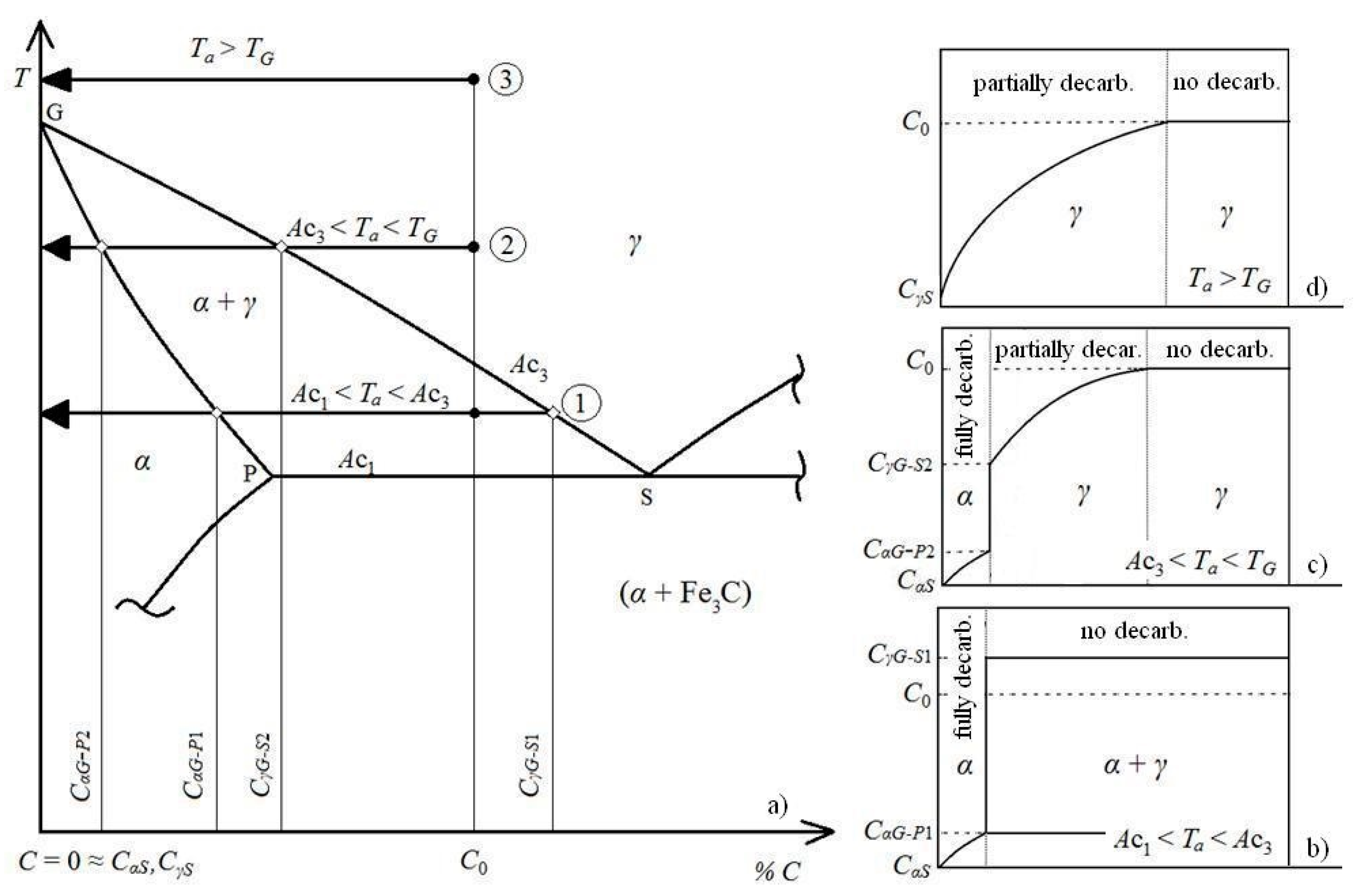

High carbon steel microstructure diagram.

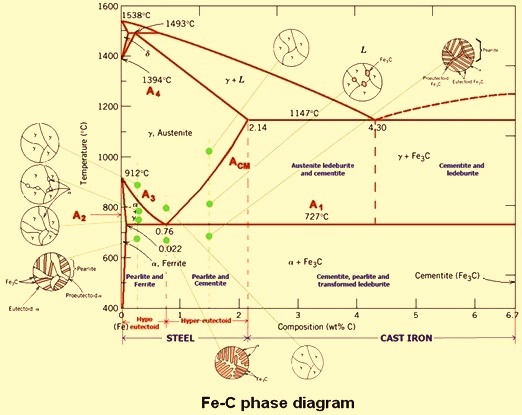

Historical description of the fe c phase diagram.

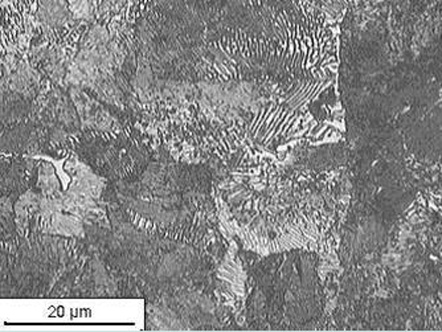

The residual phase is untempered martensite which etches lighter because of the absence.

Optical micrograph of a mixed microstructure of bainite and martensite in a medium carbon steel.

For heat treatment of steels the first resource to become familiar with is the iron cementite equilibrium phase diagram which shows the equilibrium phases in iron carbon alloys for a given temperature and composition the iron carbon equilibrium phase diagram 10 presented in figure 1 shows carbon levels up to 7 wt but steels are iron carbon alloys only up to approximately 2 wt.

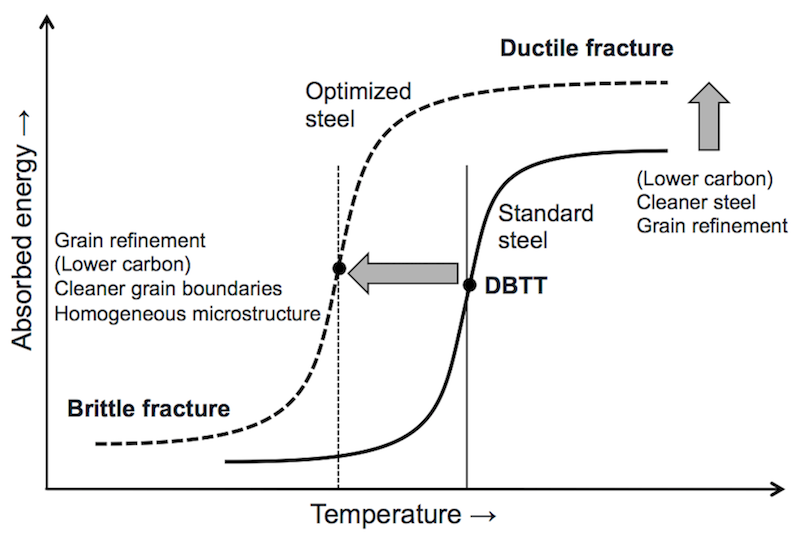

It is primarily used to improve mechanical properties or reduce eliminate distortion.

The bainite etched dark because it is a mixture of ferrite and cementite and the α b θ interfaces are easily attacked by the nital etchant used.

Austempering is defined by both the process and the resultant microstructure.

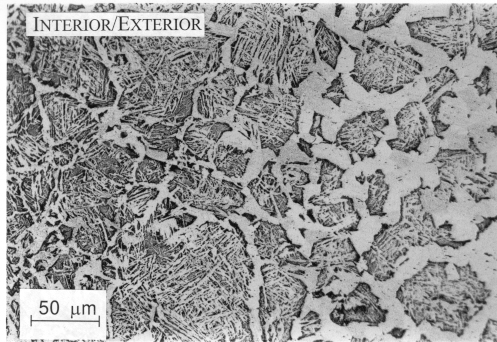

High carbon steels hyper eutectoid steels.

It is made up from a fine mixture of ferrite and iron carbide which can be seen.

The low angle variant pair density is a key factor for the recognition of low carbon steel.

To make may answer more viewable i ll add a few sem and tem images on low c steel below.

Sem tem study of low carbon steel subjected to conventional and severe pl.

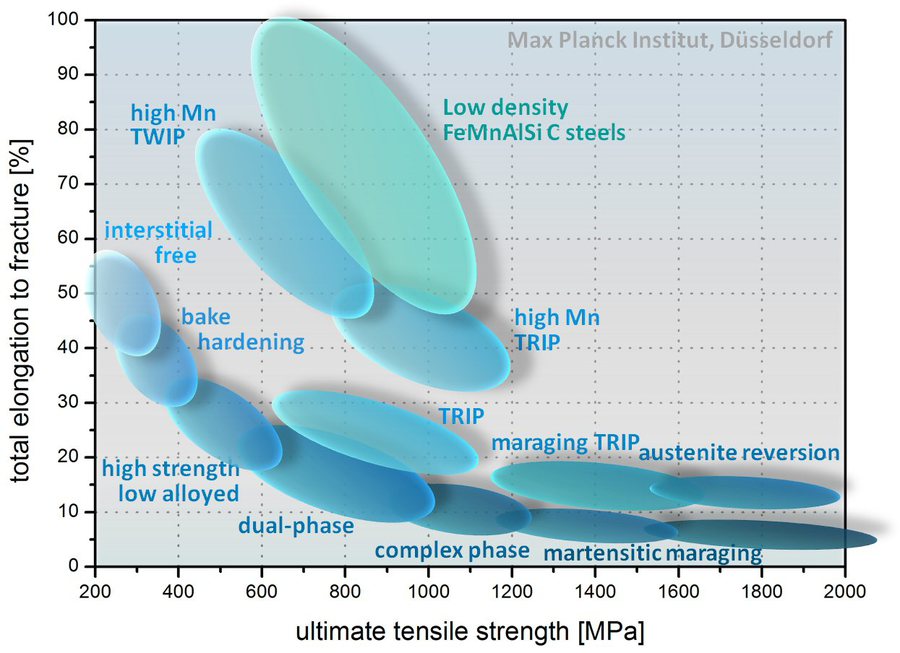

A methodology to construct microstructural diagram is proposed for characterizing the microstructure of steel.

Iron carbon phase diagram.

Figure 2 shows the microstructure of high carbon steel with about 0 8 c by weight alloyed with iron.

1 1 crystal forms and interstitial solubility of iron.

In steel it produces a bainite microstructure whereas in cast irons it produces a structure of acicular ferrite and high carbon stabilized austenite known as ausferrite.

The microstructure of steel generally refers to the specific shape size distribution and phase types of the grains in the steel.

Mechanical properties and microstructure of a high carbon steel iva tkalcec.

The microstructural diagram can be constructed by a combination of ebsd and machine learning methods.

As the c dissolved in austenite increases the iron atoms are pushed further apart.

Carbon initially influences the solidification of the steel like a solid solution the steel part of the phase diagram terefore has the typical lenticular two phase region during solidification.

Microstructure of high carbon steel.