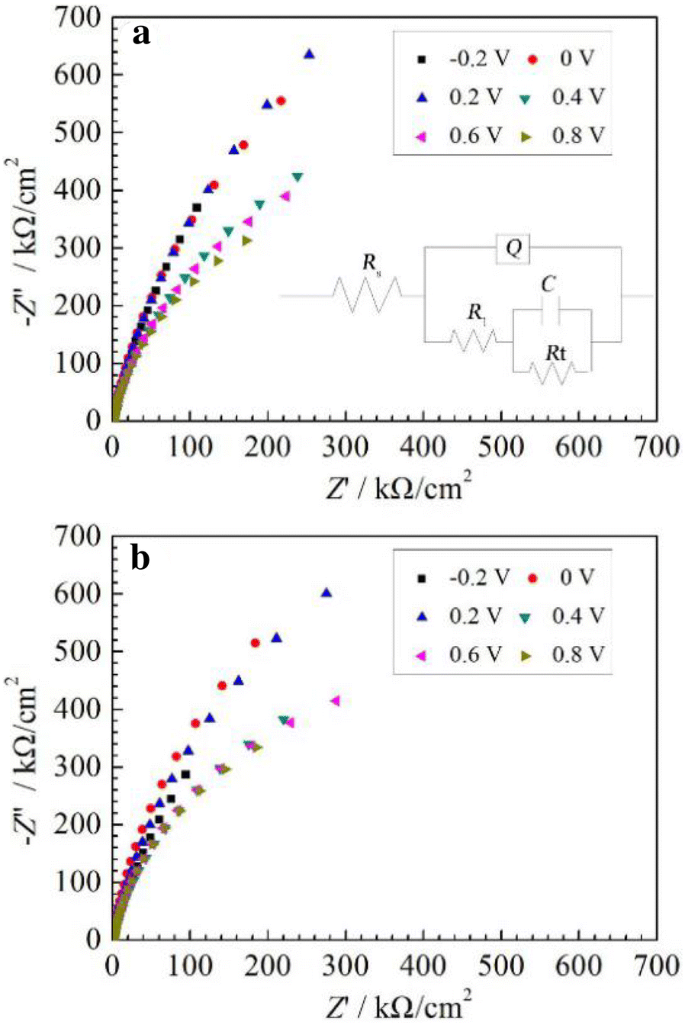

The concurrent presence of nitrogen and molybdenum has a synergistic effect on increasing resistance against both pitting and crevice corrosion.

High nitrogen stainless steel composition.

This articles explores the possibility of the use of martensitic high nitrogen stainless steels for cryotechnic bearings for aerospace applications where requirements stipulate that no crack initiation can be tolerated.

Because of this the high nitrogen steel are considered as new promising class of engineering materials.

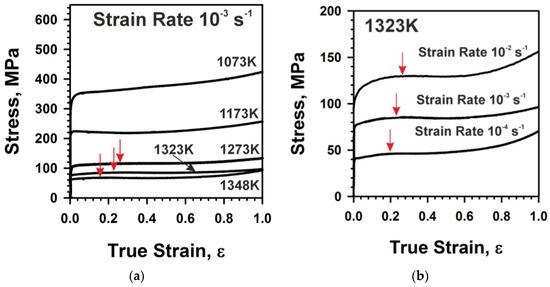

Martensitic high nitrogen stainless steels are particularly interesting because they typically exhibit high strength and ductility good corrosion resistance and reduced grain boundary sensitization.

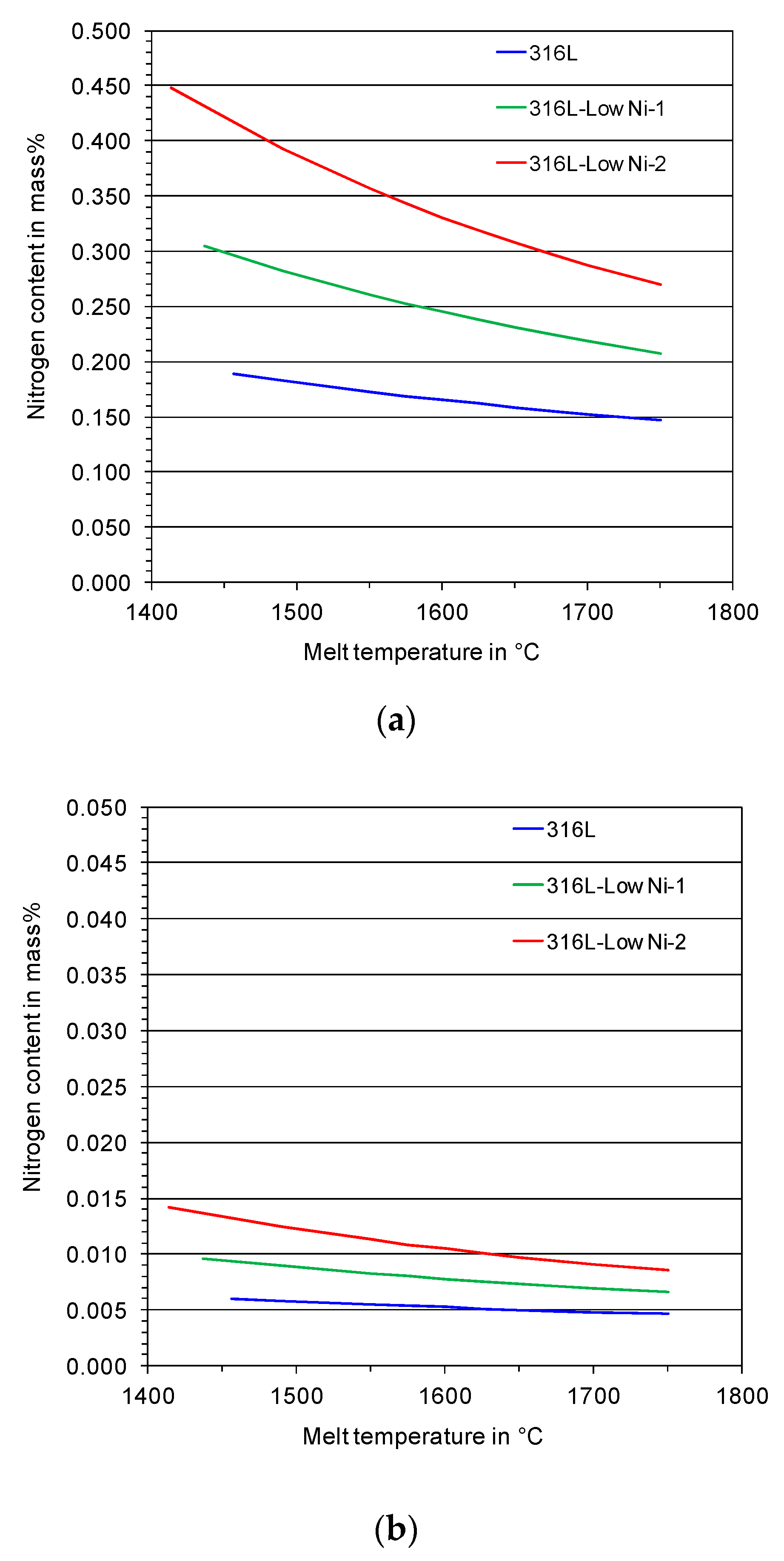

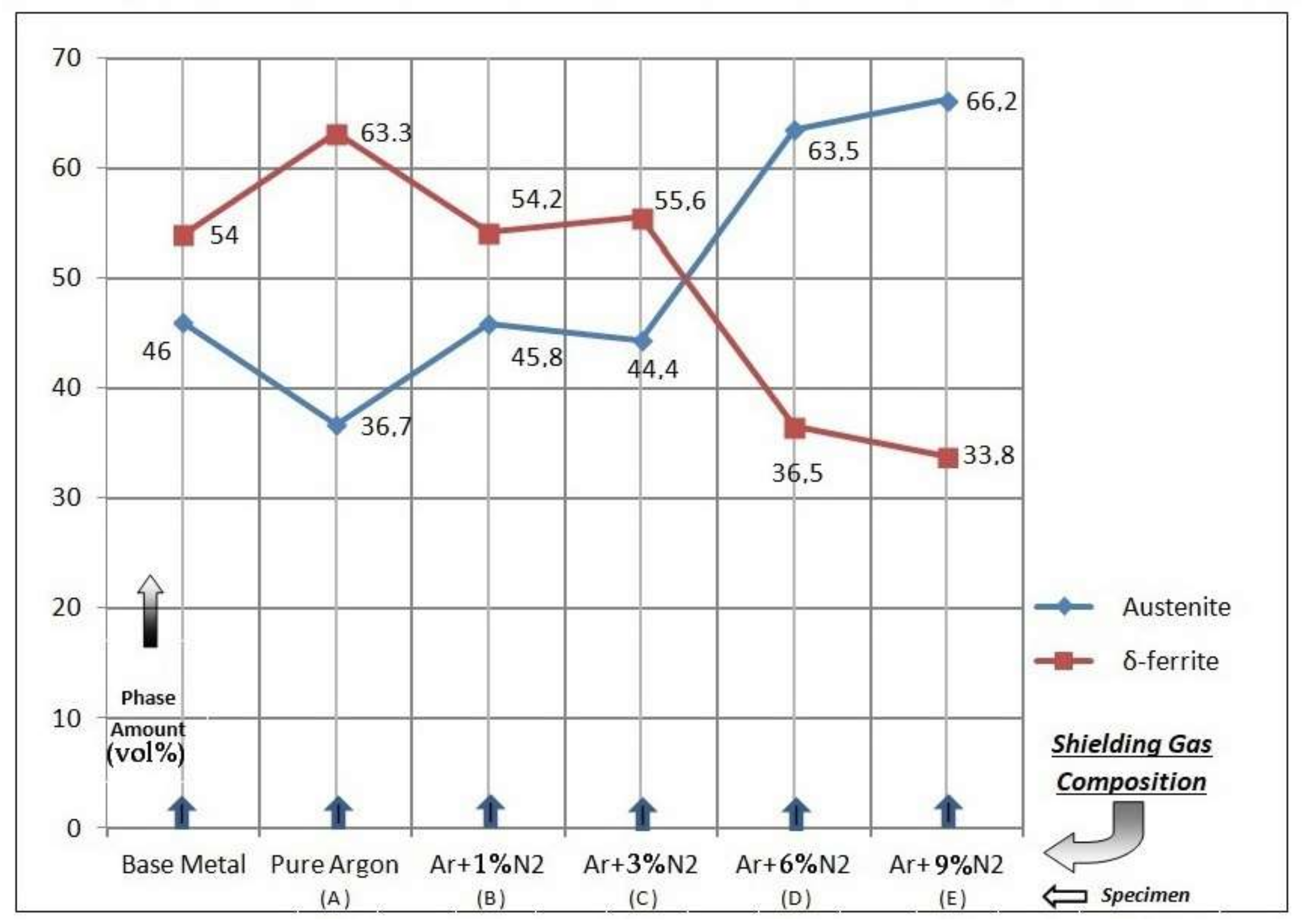

Three nitrogen rich welding wires with nitrogen content of 0 15 0 6 and 0 9 for high nitrogen stainless steel welding were developed by a modified schaeffler diagram and equilibrium phase diagram calculation.

Nitrogen in steel rebar.

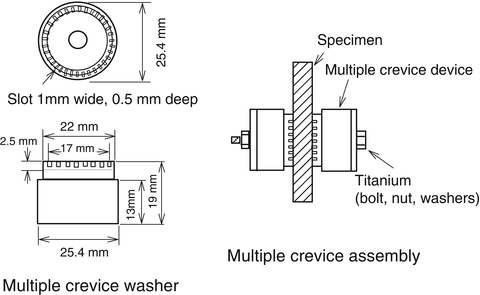

High nitrogen martensitic stainless steel shows improved resistance to localized corrosion like pitting crevice and intergranular corrosions over their carbon containing counterparts.

Furthermore it is believed that a new pren formula is required for high nitrogen stainless steels containing molybdenum and manganese.